Creating high-quality e-cigarette liquid is an art that combines science and flavor craftsmanship. As the demand for vaping continues to rise, understanding e-cigarette liquid production becomes increasingly relevant. This process requires precision and a deep knowledge of various components that make up the liquid, such as propylene glycol, vegetable glycerin, nicotine, and flavorings. For those venturing into production, it’s crucial to prioritize quality and compliance with industry standards.

Essential Components in E-Cigarette Liquid

The foundation of any good e-liquid is its base, typically a combination of propylene glycol (PG) and vegetable glycerin (VG). PG is responsible for carrying flavor and providing a throat hit akin to smoking, while VG offers a smoother experience with large vapor production. Determining the right PG/VG ratio is vital in tailoring the vaping experience to consumer preferences.

Nicotine, an optional ingredient, requires careful handling due to its potency and health implications. Producers should calculate the concentration accurately to ensure safety and satisfaction. Various nicotine levels can cater to different consumer needs, from those who prefer none to those seeking a stronger hit. Further, selecting high-quality flavors is essential. These could range from simple fruit extracts to complex dessert blends, enabling companies to distinguish themselves through unique taste profiles.

Create Your Unique Brand Identity

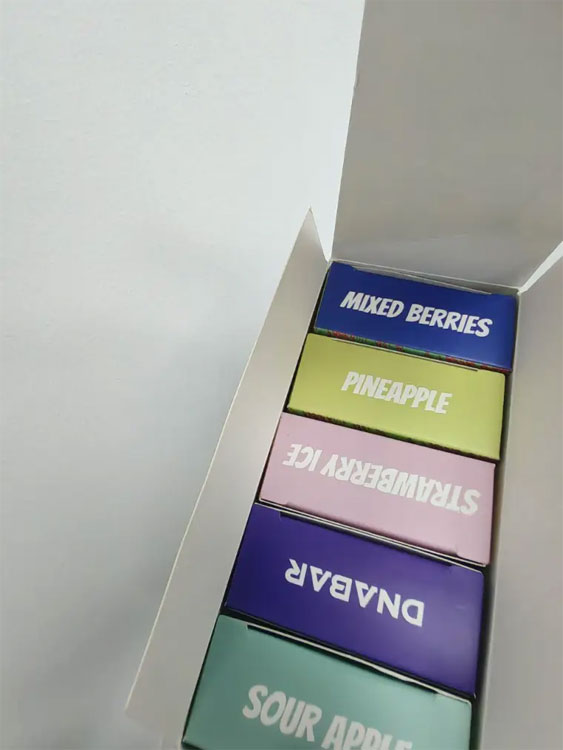

Brand identity in e-cigarette liquid production centers around uniqueness. Producers should strategically select flavor combinations that attract target demographics, from menthol enthusiasts to dessert flavor lovers. Moreover, transparency in labeling and packaging establishes trust. Clearly indicating the PG/VG ratio, nicotine content, and added ingredients on the packaging is both a regulatory requirement and a marketing strategy.

centers around uniqueness. Producers should strategically select flavor combinations that attract target demographics, from menthol enthusiasts to dessert flavor lovers. Moreover, transparency in labeling and packaging establishes trust. Clearly indicating the PG/VG ratio, nicotine content, and added ingredients on the packaging is both a regulatory requirement and a marketing strategy.

Developing a strong online presence is equally important. SEO-optimized website content can drive traffic and increase visibility. Utilizing keywords pertaining to vaping and e-liquids ensures high rankings in search engine results, reaching wider audiences.

Quality Control and Compliance

When producing e-cigarette liquids, maintaining high quality and complying with safety regulations are paramount. Producers must consistently test their products in dedicated labs to ensure purity and potency. Compliance with regulations, like those set forth by the FDA in the United States, protects companies from legal consequences and builds consumer confidence.

Investing in reliable production equipment and skilled personnel further ensures product consistency and safety. When customers feel assured about the quality of e-cigarette liquids, brand loyalty increases. Regular audits and batch testing retain product integrity, ensuring that the final liquid surpasses industry standards.

Innovations and Future Trends

The e-cigarette industry is rapidly evolving, with technological advancements shaping product trends. Innovations in e-liquid formulations focus on maximizing flavor intensity while minimizing chemical additives. At the same time, there’s a push toward natural ingredients and organic certifications, addressing consumer demand for healthier alternatives.

Adaptive strategies to tackle regulatory changes and market demands can enable businesses to stay competitive. Progressive producers anticipate shifts in consumer behavior, such as seeking eco-friendly packaging or dabbling in cannabidiol (CBD)-infused vaping liquids.

FAQ

What is the importance of the PG/VG ratio?

The PG/VG ratio determines the throat hit and vapor production of the e-liquid. Higher PG provides stronger flavor and throat sensation, while higher VG results in thicker vapor.

How can one ensure compliance in production?

Staying updated with local regulations and implementing rigorous quality control measures will ensure compliance with industry standards.

Are there trends to watch in e-cigarette liquid production?

Trends such as natural and organic ingredients, CBD infusions, and sustainable packaging are gaining traction in the market.